ขายที่ปักธงชัย วังน้ำเขียว

Logistics Management, Milk Run Logistics, Milk Run System, Logistics Systems, Logistics Company

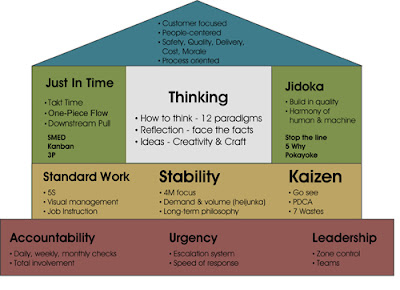

What is Toyota production system, TPS

Pending businesses today undergo challenges and forces that drive them crazy. Uprising competition between prices and product quality has sparked new inventions and new methods to survive and to aim for higher profits. One of the most interesting, yet very efficient methods is the Toyota Production System. In order to cope with products and delivery services, elimination of wastes, and quick orders from customers, this system will allow businesses to work efficiently without a need to worry about having a deficit. Another name for the Toyota production system is the JIT or the Just in Time System. As its name implies, the system strives to make best products within a limited amount of time to ensure quality and at the same time speed. It is a system that steeped deeply into a philosophy that all wastes will be eliminated. TPS is developed and established based on two concepts: Jidoka and Just in Time. The Jidoka concept works efficiently; when problems occur in machines or working systems, the working system or machines pending will stop their jobs right away in order to prevent further production of wastes, defective products, or wrong orders. The second concept, perhaps the most important one, is the Just in Time. The Just in Time concept focuses on producing products as quick as possible and to produce what is only needed by the next process in the production line to generate a continuous flow. Businesses that follow the TPS often produce high quality products on time and of best quality which enhance their productivity and raised profits as well as positive customer feedbacks.

The Concepts

The TPS involves two main concepts as described earlier in the previous paragraph. The Just in Time and the Jidoka are widely used in large businesses and corporations, especially companies that involve international trade and global communication. These two concepts fulfill customer demands efficiently by linking all production activities together, resulting in a quick production of products with elimination of wastes. The Just in Time concept involves looking at quantities of products needed to be produced and to produce them only when needed. The Jidoka concept incorporates quality check of products and all processes within a production line. By ensuring that all processes meet requirements and standards, the Jidoka strives to enhance productivity and to make mistakes and defective products visible so that quick changes and abnormalities can be addressed right away. The philosophy of Kaizen is one of Toyota’s core values which raised standards and quality of businesses. Kaizen means ‘continuous improvements’ in Japanese. As its name was written, practically, team members must cooperate and look for improvements in all categories and in all operations. Kaizen requires clear goals and objectives; it brought positive actions and thoughts on what SHOULD be produced, not what CAN be produced.

The Environment

It is very important for businesses and companies to be greatly aware of their environment, which includes: safety and hygiene. The TPS considers the environment o be one of the most important factors in moving the process and operations forward. The three Rs: reuse, reduce, and recycle helps businesses to be able to analyze the effects of every stage in making products that includes development, operation, and recycling.

Health and Safety

Health and safety is always one of the most important issues to be concerned of. Toyota Production System does its job efficiently; by monitoring all processes and with the Jidoka system where all operations would stop if any abnormalities are detected, is indeed a safety assurance for companies and huge corporations. The system itself has ensuring back-up plans to produce products if any error is found right away during work time. The flexibility of working as a team in the Toyota Production System results in quick alerts for changes or tasks to be done efficiently without having to worry about other issues that might bring them out of topic and focus. In all cases, all work-stations are well designed in order for working to be easy and understandable. Though equipments and machinery are technologically developed for efficiency and to enhance great productivity, the instructions and steps on how to use them are simple and well organized. All employees and workers must undergo training courses in order to learn about safety buttons and systems. The teams also have to give in suggestions on how the system should improve their safety and ensure that all products will be produced efficiently, correctly, and that they passed through all operations and requirements.